Equipments

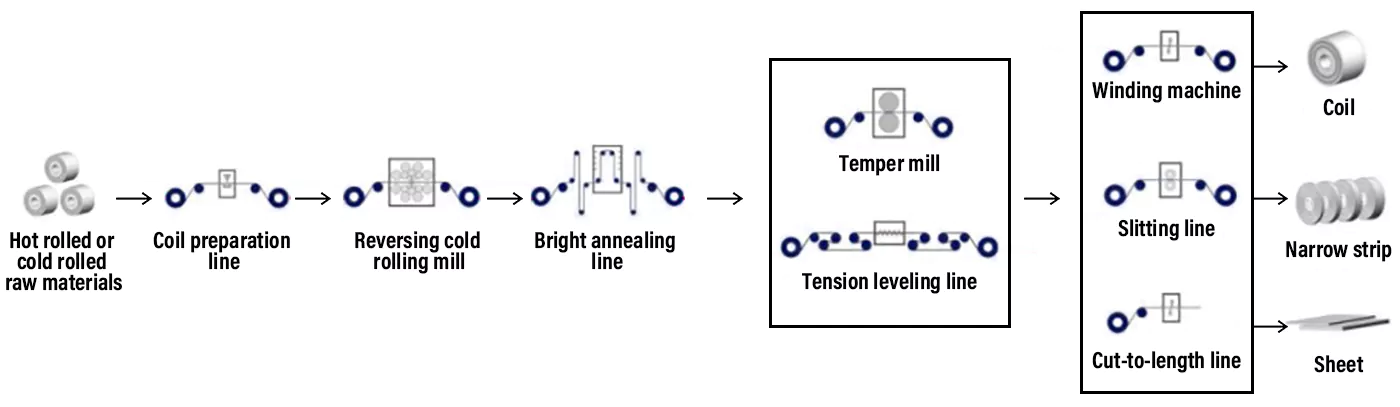

Process flow of precision cold rolled stainless steel sheet and strip

In this process flow, the hot-rolled or cold-rolled stainless steel raw materials are rolled to the target thickness by a high-precision reversing multi-high cold rolling mill at ambient temperature, and the bright heat treatment is carried out to have the surface effect and mechanical properties required by customers, and then the process of tempering or tension leveling is carried out to optimize the surface and shape of the stainless steel sheet and strip, and the products’ mechanical properties are improved to achieve the mechanical properties required by the precision cold-rolled stainless steel sheet and strip; the precision cold-rolled stainless steel sheet and strip produced through this process flow is soft in terms of mechanical properties.

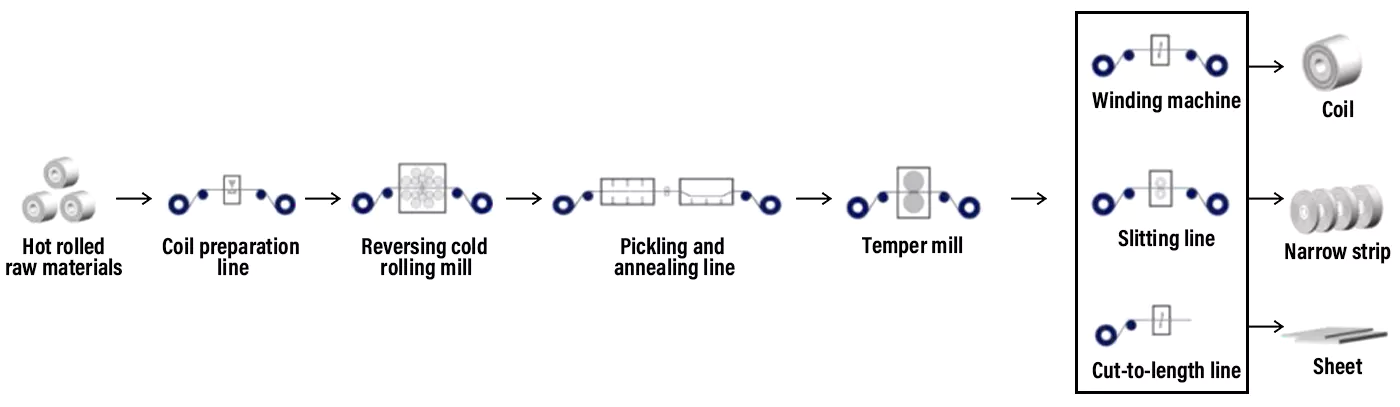

Process flow of pickling annealing cold rolled stainless steel sheet and strip

In this process flow, the hot-rolled stainless steel raw materials are rolled by the cold rolling mill for multiple passes to reach the target thickness, and then the pickling and annealing process is carried out to achieve the required mechanical properties and surface effects; finally, the temper process is carried out to optimize the surface quality of the stainless steel sheet and strip. The wide width cold-rolled stainless steel sheet and strip produced through this process flow has a 2B surface and belongs to the soft cold-rolled stainless steel sheet and strip in terms of mechanical properties.

Hard-Core Equipment

Yongjin is equipped with the special equipment for ultra-thin precision stainless steel sheet and strip (which are independently developed or imported by Yongjin), and adopts the internationally advanced automatic control system, especially, the annealing and pickling line adopts the internationally most advanced nitric acid-free pickling process and acid regeneration system, ensuring the stability of pickling quality and the goal of zero emission. Yongjin always adheres to the tenet of "brand first, green development", and has truly achieved the goals of high quality production, high efficiency, low energy consumption and environmental protection.

FIVES DMS [ France ]

Reversing stainless steel strip cold rolling mill

- It is manufactured by FIVES, a world-class company, adopts Siemens 3700 series control system, and reaches the international leading level in the aspect of design and manufacturing. It is mainly used to produce 300 series and 400 series precision stainless steel strip, with an annual output of 100,000 tons.

- Mainly used on the production of series 300,400 precision stainlesssteel strip.

- Annual output can reach 100,000 tons.

Developed and Designed by Yongjin

20 High Cold Rolling Mill

- Yongjin's 20-High Cold Rolling Mill is based on Primetals SIMATIC fully integrated automation platform,using S 7416-3 and FM 458 controllers and WINCC interface. The transmission uses Primetals medium-voltage SM150 and S120 transmission controllers, which have high speed control accuracy, fast response time and high stability. The whole line adopts the network structure of Plofibus+Plofinet, which has fewer faults, faster network speed, stable tension control accuracy within 2%,acceleration/deceleration control within 4%, thickness accuracy within 0.6%, and plate shape accuracy within 8 lU. Maximum speed is 700 m/min.

- Mainly used for series 300,400 precision stainless steel strip. Annual output reachs 100,000 tons.

EBNER [ Austria ]

Vertical Bright Annealing Line

- It is jointly manufactured by world-class EBNER and Yongjin Metallurgical Equipment Co., Ltd., and has the overall height of 50 meters. The line adopts muffle structure (natural gas heating), and the furnace is equipped with furnace gas recovery and purification system, so as to effectively improve the purity of protective gas and ensure the high quality of products.

- It is mainly used to produce 300 series and 400 series precision stainless steel strip, with an annual output of 60,000 tons.

CHUGAI RO [ Japan ]

Vertical Bright Annealing Line

- Equipped with advanced furnace temperature control system. Heating method is electric, the atmosphere gas is ammonia decomposition gas (hydrogen and nitrogen), it is a vertical brick furnace.

- Ensure the product performance is stable and uniform.

- Mainly used on the production of 300 and 400 series precision stainless steel thin strip products.

Developed and Designed by Yongjin

Reversing Stainless Steel Strip Temper Mill

- It is independently developed and designed by Yongjin Metallurgical Equipment Co., Ltd. and manufactured by Changzhou Baoling Heavy & Industrial Machinery Co., Ltd. for its main body; its control system PLC adopts Siemens S7-400 series, and its design and manufacturing reaches the world advanced level.

- It is mainly used for processing 300 series and 400 series soft precision stainless steel strip.

UNGERER [ Germany ]

Tension leveling line

- It is manufactured by the world-class UNGERER Company and equipped with the highest level of automatic control system and applies the mode of combining high tension flatness measurement system (UMSi) with low tension flatness control system (UMS).

- It is mainly used for producing 300 series and 400 series of soft or hard precision stainless steel strip.

磨砂机

BURGARDT + SCHMIDT [ Germany ]

High-Precision Slitting Line

- Equipped with the most advanced Siemens automation control system in the world.

- lt is majorly used for the production of 200,300,400 series of soft and hard precision stainless steel strip with a thickness of 0.05mm to 1.0mm and a width of 20mm to 1250mm.

- BURGARDT +SCHMIDT high-precision longitudinal shearing unit will not cause new defects on the surface.