Process Flow

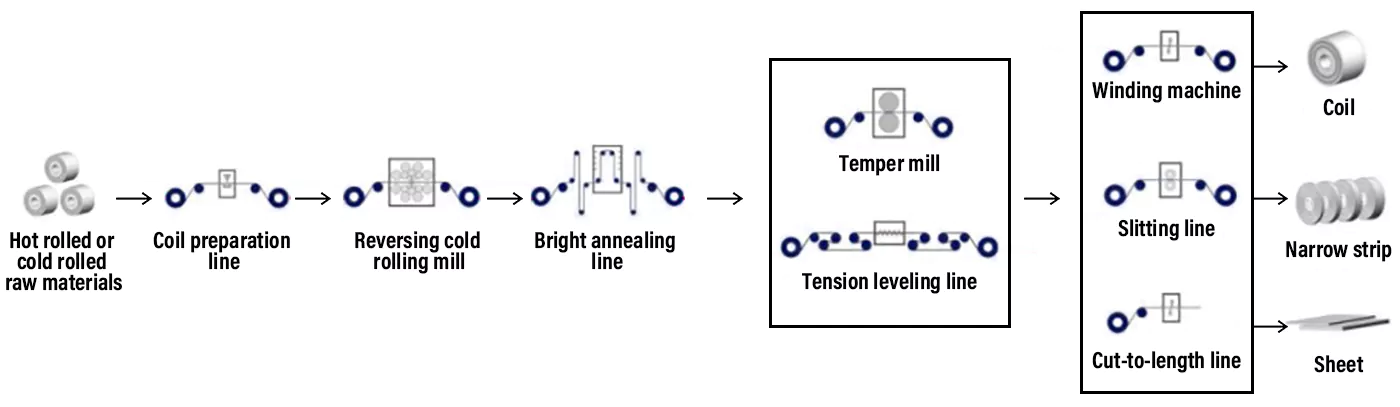

Process flow of precision cold rolled stainless steel sheet and strip

In this process flow, the hot-rolled or cold-rolled stainless steel raw materials are rolled to the target thickness by a high-precision reversing multi-high cold rolling mill at ambient temperature, and the bright heat treatment is carried out to have the surface effect and mechanical properties required by customers, and then the process of tempering or tension leveling is carried out to optimize the surface and shape of the stainless steel sheet and strip, and the products’ mechanical properties are improved to achieve the mechanical properties required by the precision cold-rolled stainless steel sheet and strip; the precision cold-rolled stainless steel sheet and strip produced through this process flow is soft in terms of mechanical properties.

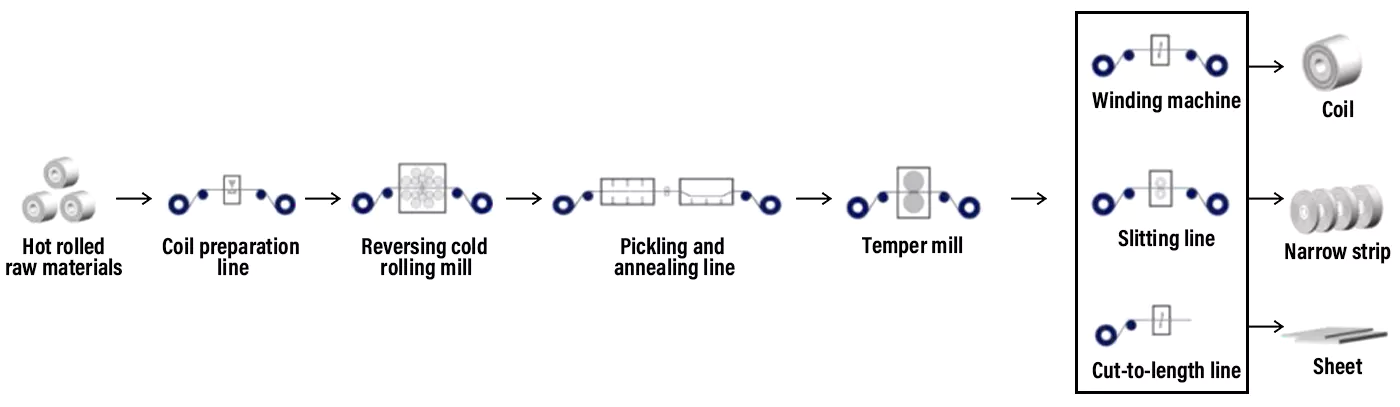

Process flow of pickling annealing cold rolled stainless steel sheet and strip

In this process flow, the hot-rolled stainless steel raw materials are rolled by the cold rolling mill for multiple passes to reach the target thickness, and then the pickling and annealing process is carried out to achieve the required mechanical properties and surface effects; finally, the temper process is carried out to optimize the surface quality of the stainless steel sheet and strip. The wide width cold-rolled stainless steel sheet and strip produced through this process flow has a 2B surface and belongs to the soft cold-rolled stainless steel sheet and strip in terms of mechanical properties.